- Title

-

A multi-depth spiral milli fluidic device for whole mount zebrafish antibody staining

- Authors

- Ye, S., Chin, W.C., Ni, C.W.

- Source

- Full text @ Biomed. Microdevices.

|

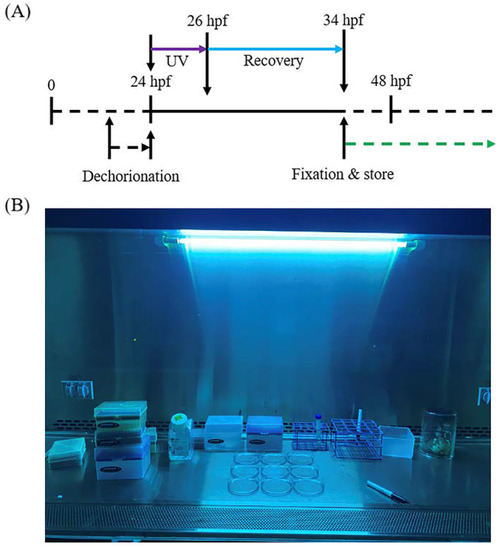

Zebrafish embryo Caspase-3 cleavage activation and sample preparation. |

|

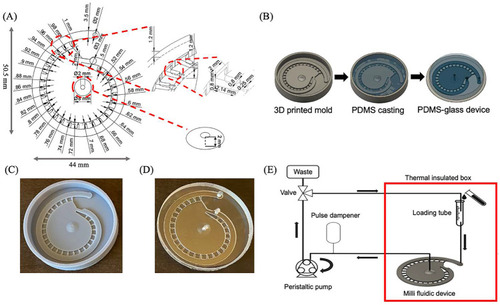

Multi-depth spiral milli fluidic device for zebrafish immobilization and antibody staining. |

|

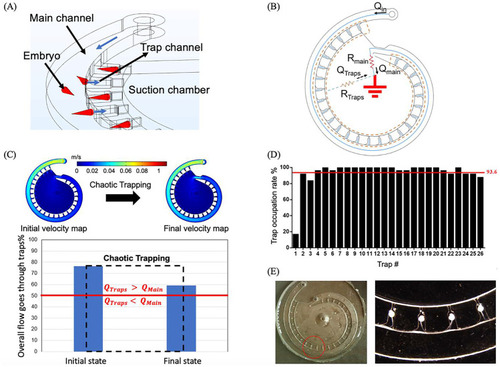

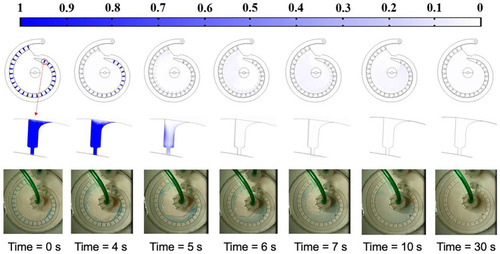

The zebrafish embryo trapping principles and validations. |

|

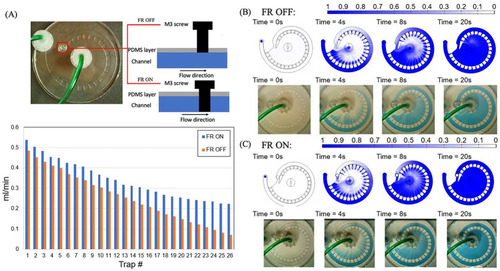

On-chip flow settings for the multi-depth spiral device. |

|

The flushing time estimation. |

|

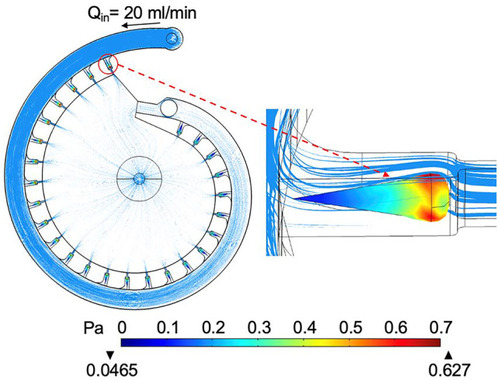

The simulated body shear stress on the fixed zebrafish embryos during on-chip perfusion. The embryo in the first trap is selected to show the maximum shear stress level and the shear stress distribution. The flowrate is set at 20 ml/min and the FR is turned on |

|

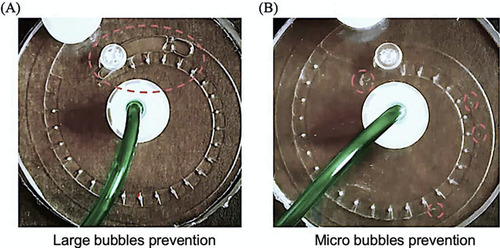

Bubble prevention in the milli fluidic device. |